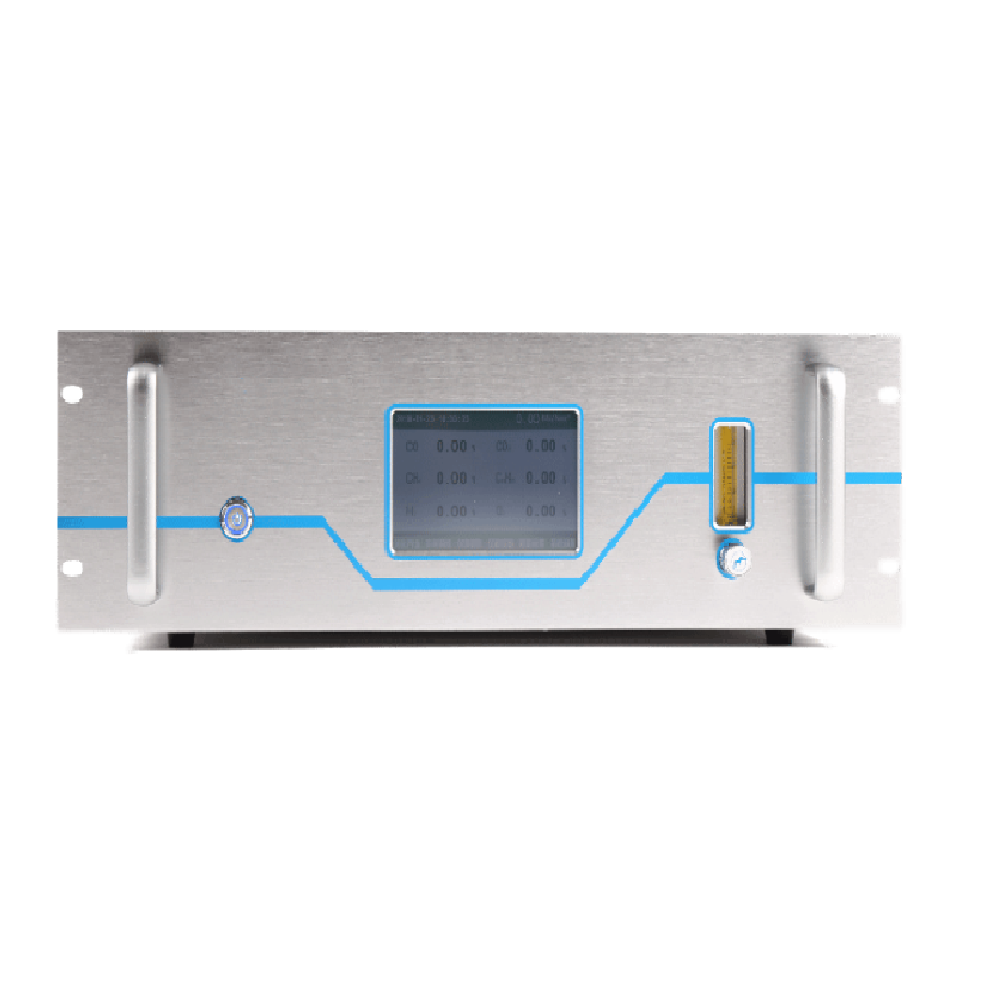

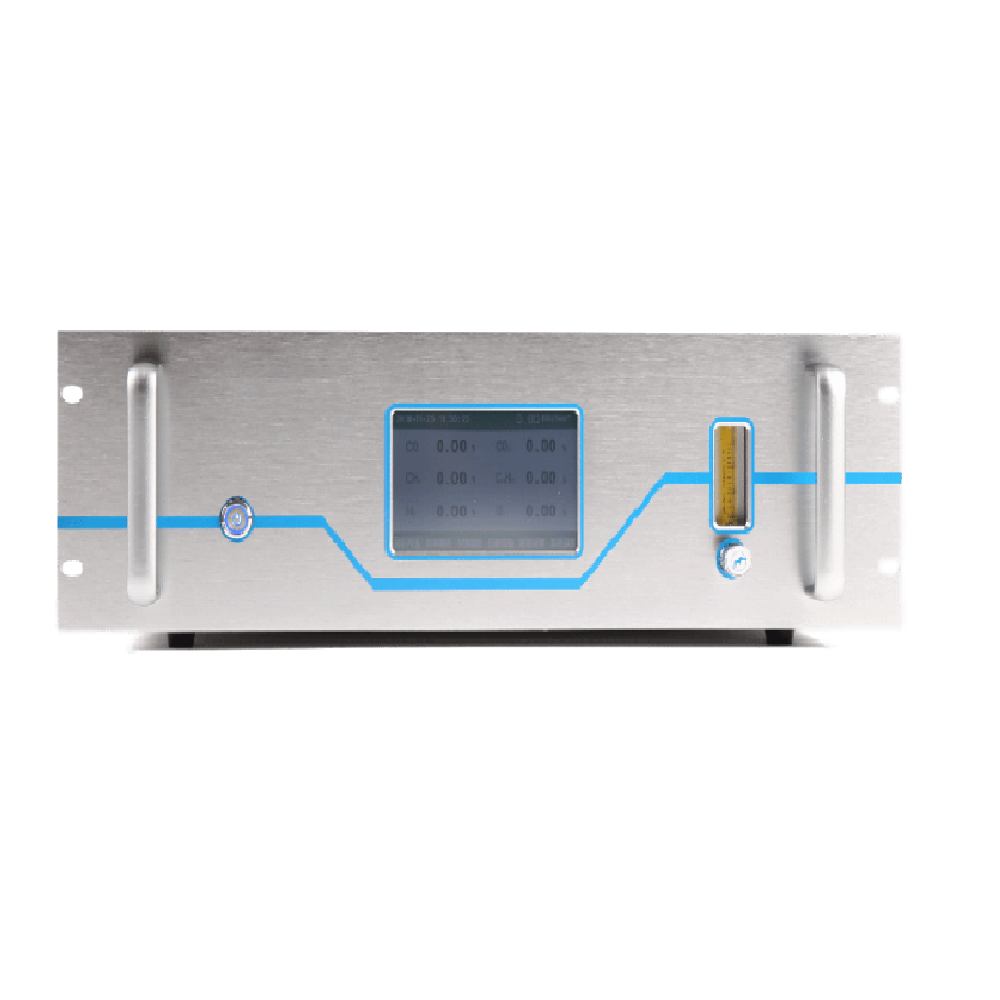

New 3U syngas analyzer

Syngas Analyzer CH4/CO2/CO/H2/O2/CxHy

- Detecting Gas: CH4/CO2/CO/H2/O2/CxHy

- Measure Range: 0%vol-100%col

- Display: colorful touch screen

- Output: RS232/RS485/4-20mA

- Product description: Rack 3U Syngas Analyzer CH4/CO2/CO/H2/O2/CxHy

I. Introduction

Online Continuous Syngas Monitoring System SYN-600 R consists of online continuous syngas analyser, gas conditioning system, washing system, PLC system, industrial computer system(optional). It can measure CH4,CO2,CO,CnHm,O2 and H2 at the same time in one unit, and calculating heating value in MJ/M3 or Kal/m3. It has water bubbler washing system to remove tar, and gas cooler as well as two precise filters to remove moisture and dust. All the measurement data and system status can be transited the centre control system by 4-20mA, RS485 or PLC system.

II. Features

ŌĆó Using 5'' TFT LCD touch screen

ŌĆó Measurement value display/real-time curve display

ŌĆó Calibration menu and alarm setting with password protection

ŌĆó One set back to factory setting

ŌĆó PLC automatically control sampling, water washing, diagnosis

ŌĆó Two precise gas filter and gas cooler to remove dust and moisture

ŌĆó Optional with industrial computer to realize remote data transmission.

III. Specifications

|

Measurement |

CO, CO2, CH4, CnHm, O2, H2 and gas calorific value calculation |

|

Calculation |

High Heating Value or Low Heating Value in MJ/m3 or kcal/m3 |

|

Technology |

CO, CO2, CH4, CnHm: proprietary dual beam NDIR detectors O2: industrial electrochemical cell H2: MEMS thermal conductivity detector |

|

Ranges |

CO/ CO2:/CH4 / H2: 0-100%, CnHm : 0-10%, O2: 0-25% Other ranges customizable on request without price increase |

|

Resolution |

0,01% |

|

Accuracy |

CO/CO2/CnHm/CH4’╝Ü┬▒2%FS’╝øH2/O2’╝Ü┬▒3%FS |

|

Repeatability |

Ōēż 1% |

|

Gas conditions |

Flow:0.7L-1.2/min, internal gas sampling pump, external flow meter with needle valve Pressure:2kPaŌēż inlet pressureŌēż 50kPa Quality: No dust, moisture, tar (external safety filter and optional gas washing unit) |

|

Operating conditions |

Tamb : -5┬░C to 50┬░C / Pamb : 86 to 108 kPa / RH : 0-90% non-condensing |

|

Response time (T90) |

Ōēż 15 sec (NDIR) |

|

Communication interface |

4-20mA; RS232/RS485 |

|

Power supply |

External 11V-220 VAC-50Hz |

|

Dimensions and weight |

Gas analysis system :1800(L) x 800 (H) x 800 (W) mm /200-250kg Water bubble washing system: 1200 (L) x 800 (H) x 300 (W) mm / 75-100kg |

IV.

Applications

- coal chemical process

- steel making process as blast furnace, converter, coking, direct iron ore smelting reduction

- syngas production from Biomass and coal gas gasification processes

Categories

- New 3U syngas analyzer

- Syngas analyzer portable

- 24-hours online syngas system

- Biogas analyzer portable

- Wall-mounted biogas monitoring s

- Ultrasonic gas flow meter

- Pertier/compressed gas coolers

- 0.1um/1um/2um/5um gas filters

- Gas flow alarm sensor

- 120Ōäā/180Ōäā heated sampling line

- Moisture alarm sensor

- 5RPM-10RPM/m peristaltic pump

Latest News

Contact Us

Contact: Roy Chung

Phone: +86-13871445824

Tel: +86-27-87961816

Add: NO.508, Buiding2, NO.6 Huashi Yuan North Road, Eastlake Hi-tech Development Zone, 430073,Wuhan